Precision is the cornerstone of any weighing balance or scale. This is more so in a pharmaceutical industry or a research laboratory where even a slight deviation in readings can give erroneous results with serious consequences. For example, in the manufacture of medicine each ingredient carries a certain weight, which if altered, can change the properties or efficacy of the medicine altogether. Also, minor deviations in measurement can give different outcomes, which can have a serious bearing in the area targeted by research.

Precision is the cornerstone of any weighing balance or scale. This is more so in a pharmaceutical industry or a research laboratory where even a slight deviation in readings can give erroneous results with serious consequences. For example, in the manufacture of medicine each ingredient carries a certain weight, which if altered, can change the properties or efficacy of the medicine altogether. Also, minor deviations in measurement can give different outcomes, which can have a serious bearing in the area targeted by research.

This brings us to the question of the steps to be taken to ensure precision. The first and foremost will be to procure the weighing balance from a reputed company known for its experience and expertise in designing such weighing solutions. The second is concerned with calibrating the scale periodically at the actual location. Let’s discuss the second aspect to begin with. There are a number of factors that can impact the functioning of a precision balance used in a laboratory or research centre such as gravitation, wind pressure, magnetic field, temperature, and vibrations. Importantly, these factors should be considered while calibrating a balance.

How can Gravitation Impact the Reading of a Precision Balance?

One of the reasons why calibration of balances should be done is the effect a location specific gravitation field can play on the object to be weighed. Let’s understand, the gravitation field is not uniform across the world. For example, as you move away from the centre of the earth the strength of the gravitation field reduces. Moreover, the field changes with regard to the mean sea level, that is, stronger at a lower level and weaker as one goes up a mountainous region. Hence, the same precision balance will give readings with slight variations when used in a plain or a hilly area thus the need for a calibration.

How Can Calibration be Beneficial?

- Rules out variations in measurements based on the above mentioned factors thus leading to a greater degree of reliability

- Reduces the cost, which otherwise would have to be accounted for while doing a rework or in case of a product recall

- Passes various compliance tests like Euramet cg-18 conducted as part of the audit, both at the internal and external level

- Confirms the quality of a precision balance and helps identify the ones suffering the effect of depreciation

- Involves hidden costs and risks like producing inferior quality of products and the loss of brand value

In addition to carrying out periodic calibration, you must procure the scales from a reputed company with a known brand name like HiWEIGH. The reason being a reputed company will not compromise on the quality of its products, for creating a brand value takes time and helps the company to build customer trust and rake in profits on a long term basis.

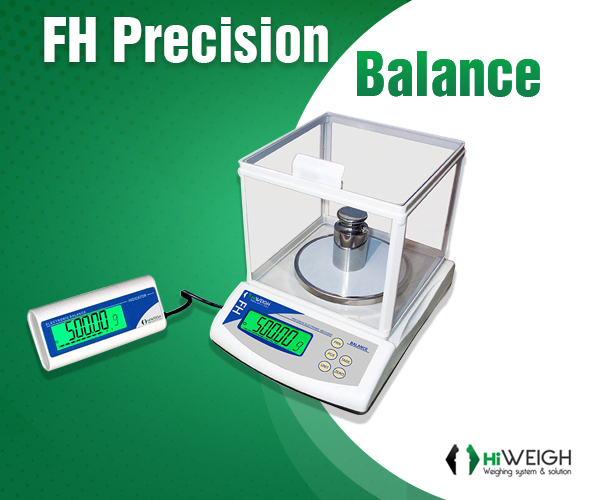

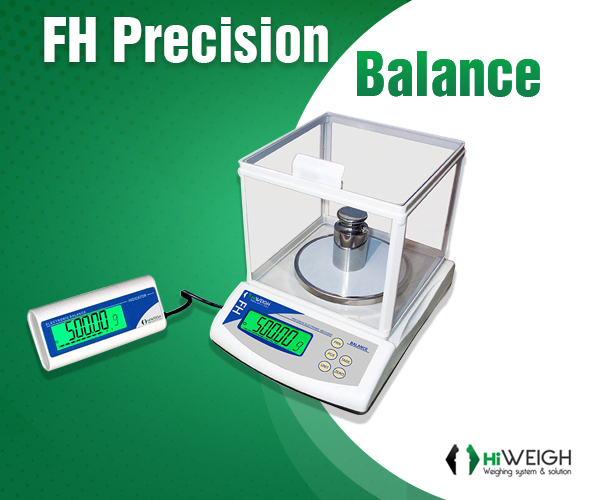

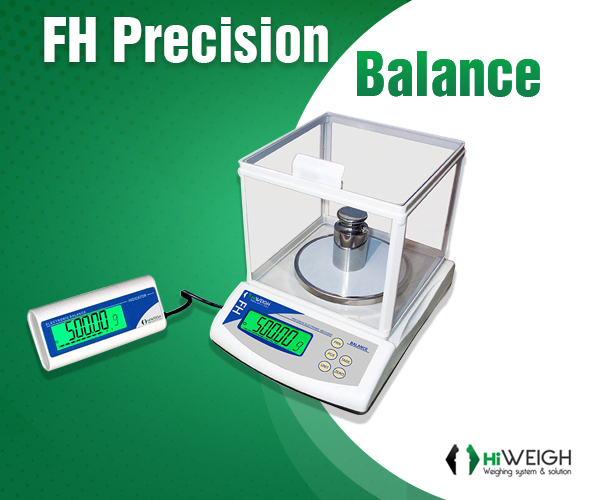

Hence, by being in the business of developing innovative weighing solutions for more than eighteen years, the ISO 9001 company HiWEIGH from China has products that are quality certified from OIML/NTEP and ISO17025 respectively. You can get a range of precision balances for laboratories namely, BTH, BJA, JT, FH, and BLB with advanced features and at cost effective rates.

Conclusion

The role of a precision balance is very important to determine the outcome of a research or a pharmaceutical product like a medicine. Thus, procuring such balances from HiWEIGH and routinely calibrating them should be undertaken.