Calibration is essential for accurate measurement. In many different fields and applications, calibration weights are essential for ensuring measurement accuracy and traceability. That’s why we aim to explore the physics underpinning calibration weights, including how they are made, how they are calibrated, and how crucial traceability is to preserving measurement accuracy, in this post.

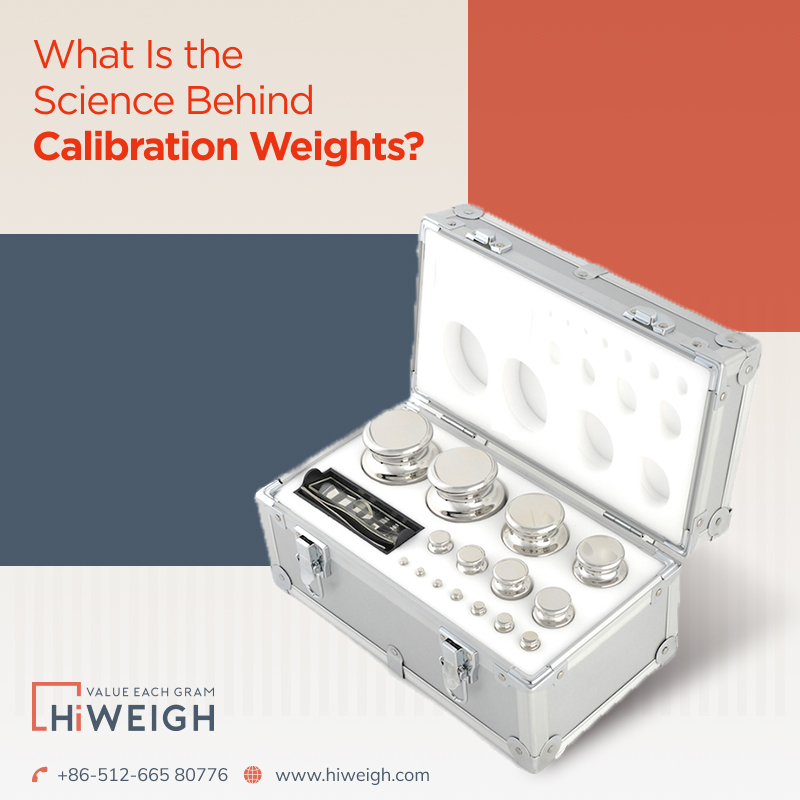

Basics of Calibration Weights

Precision tools called calibration weights are created to have a known and precise mass. They are often constructed from materials like brass, aluminium, or stainless steel. Each class and size of China calibration weights is created to satisfy a particular set of calibration criteria. For ease of identification, the weight value is typically engraved on the weight itself.

Construction and Material Selection

The calibration weights’ design is crucial to their accuracy. To reduce the impacts of temperature variations, corrosion, and magnetism, significant consideration goes into the selection of the material. To preserve their bulk and shape integrity over time, the weights are frequently constructed with extreme accuracy. Usually, they are handled gently to avoid contamination or damage that would impair their accuracy.

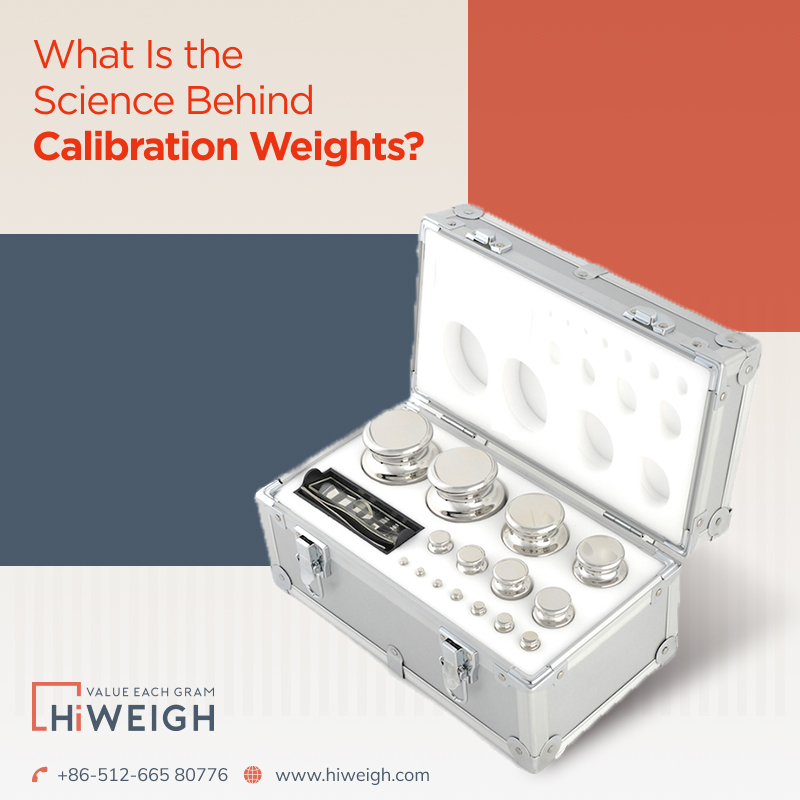

Calibration Processes

To ensure their correctness, calibration weights go through extensive calibration procedures. With the use of extremely accurate balances or weighing equipment that can be traced to local, national, or worldwide standards, accredited calibration laboratories do the calibration. The procedure entails contrasting the calibration weight with established reference standards. By doing this, the calibration weight is guaranteed to represent the stated mass precisely.

Traceability and International Standards

The essential component of calibration is traceability. Against reference standards that may be traced to accepted national or international standards, such as those kept by national metrology institutions, calibration weights are calibrated. This network of comparisons, or traceability, ensures the precision and comparability of measurements across various laboratories and businesses.

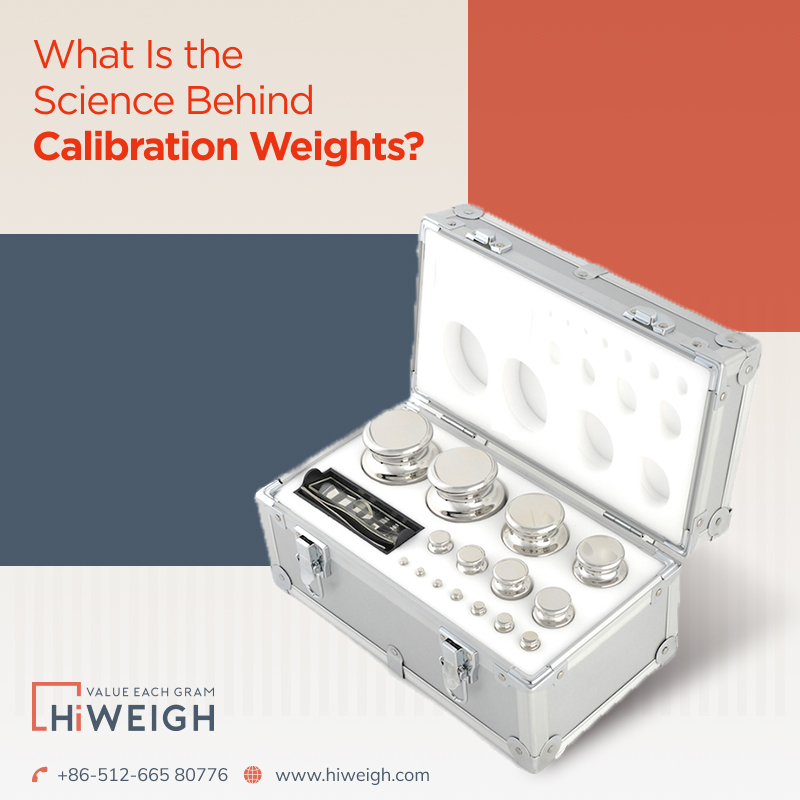

Maintaining Calibration Accuracy

Like any precise device, calibration weights need routine maintenance to maintain their accuracy. Their accuracy may be impacted over time by elements including handling, the climate, and wear. They must be periodically recalibrated to ensure their accuracy and make adjustments as necessary. To preserve the weights’ dependability, it is crucial to treat them cautiously and adhere to the suggested calibration intervals.

Importance of Calibration in Various Industries

A variety of businesses, including manufacturing, food processing, farming, research labs, and the pharmaceutical industry, employ calibration weights. For the purposes of guaranteeing product safety, regulatory compliance, and quality control in various businesses, precise measurements are essential. Companies may validate measuring equipment, maintain process control, and give customers trust in their data by using calibration weights.

Legal Metrology and Trade

The certification and calibration of particular measuring instruments are required by legal metrology laws in a number of countries. China calibration weights play a significant role in the calibration of weighing instruments utilised in business, such as industrial weighing equipment, agriculture or scales in supermarkets. These weights aid in the guarantee of precise and fair transactions by verifying the accuracy of industrial weighing apparatus.

Advancements in Calibration Technology

The calibration industry has seen technological improvements that have produced more accurate and effective calibration procedures. Higher calibration throughput and fewer human mistakes have been made possible by automated calibration systems, robotic manipulation of calibration weights, and enhanced software algorithms. The accuracy and dependability of calibration operations are further improved by these technical developments.

Final Thoughts

The foundation of measurement accuracy and traceability is calibration weights. The reliability and comparability of measurements across industries are ensured by their design, calibration procedures, and adherence to traceability requirements. Organisations may appreciate calibration weights’ crucial role in preserving measurement accuracy, adhering to laws, and guaranteeing the quality and safety of their goods and processes by having a strong grasp of the science underlying them. Businesses can rely on precise measurements and foster trust in their operations by giving appropriate calibration and routine recalibration a high priority.